Electronic devices have changed our living style completely. These devices are made of different electronic components. Nowadays these components are used in every field. The electronic components can be categorized into two parts- Active components and Passive components. Both are important, but passive components are the backbone of the electronic industry. A lot of knowledge and research is required to buy passive components. In this blog, we will discuss various passive components and sectors where they are used.

Passive components- These are the components which do not require an external energy source to operate. The main components that are covered under this category are-

- Resistors

- Inductors

- Capacitor

These components are used in every electronic device that you have in your hand or you use at your house. The investors spend a huge amount of money in the advancement of these components to enhance their quality as well as performance.

The fields where these components are used are- industries, aircrafts, defense, forecasting systems. In the next part, we will discuss the importance of electronic components in the air crafts.

Passive Components in Aircrafts-

Aircrafts indeed are packed with all kinds of electronic components. You may know one or two components, but for those who do not, we will discuss some of them.

- Passive components help in improving the performance of "black box" and also in minimizing the size of it. It resides in every plane, whether it is a fighter plane or an Airbus. This black box is the most important unit of an aircraft. Basically, it is a recorder that records the recent history of the sounds in the cockpit, including the conversation of the pilots and recording of flight data.

- Then is the cockpit, it is a compartment for the pilot, and sometimes for the crew members, in an aircraft or spacecraft. It totally works on the electronic components. Hundreds of components are installed in a cockpit. Some of them are- integrated warning system, touch screen, and a communication system.

- Electronic components are responsible for proper functioning of the engine. The pilot receives information like- weather condition, surroundings, and speed. In case of fighter planes, electronic system provides target data, navigation, and flight instrument data. These systems are made of different transistors, resistors, relays, hybrid microcircuits, LED’s, capacitors, transformers, and inductors.

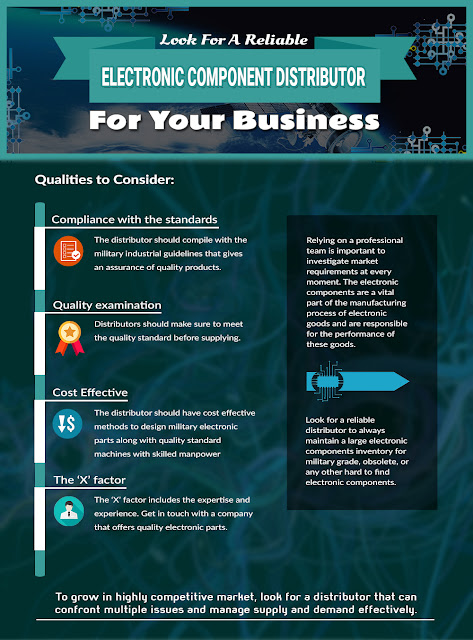

Apart from the aircrafts, there are a number of sectors where passive components are used. So, it is very important for the manufacturers of the electronic devices to buy passive components from a reliable and trusted supplier.